CFD Process Automation

Experience with CFD shows that CFD simulations are complicated, error-prone and results seem to depend on

the engineer. Among the reasons for this are the shear amount of options a user of CFD software is subjected

to. At MANTIUMCAE CFD simulations are automatically set up, analyzed and post-processed using

MANTIUMWFlow. This software eliminates most user errors and checks for convergence. So no one can miss or

overlook too high residuals or non-converged integral values. This ensures that our clients always receive

comparable simulations with everything that should be checked off of a list, actually being checked off. As

visual post-processing is also automated, all pictures will be absolutely comparable.

MANTIUMWFlow receives geometries, checks them, if necessary creates a surface mesh and then positions them. This simple step already eliminates many user errors as the geometry will be in the right dimension and a car will not have a length in the range of milli- or kilometers.

MANTIUMWFlow then sets up and runs the CFD simulation, again minimizing user input. If the solution is converged or not is evaluated automatically based on a set of monitored properties

|

|

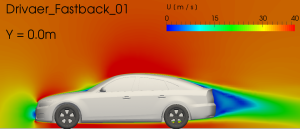

| Automating entire CFD workflows ensures comparable results. As the post processing is also automated the results can also be compared visually. | |

MANTIUMWFlow is a very important tool at MANTIUMCAE as it enables the engineers to focus on our clients’ products and not on doctoring and keeping simulations alive. Automating and documenting workflows ensures that our clients can rely on having comparable CFD simulations even when they come up with new designs months after the first simulations have been performed. If you are interested in CFD consulting or have any questions, please feel free to contact us.

The DriveAER model is supplied by Institute of Aerodynamics and Fluid Mechanics of the TU Munich.