Breaking limitations

The Challenge of Traditional CFD

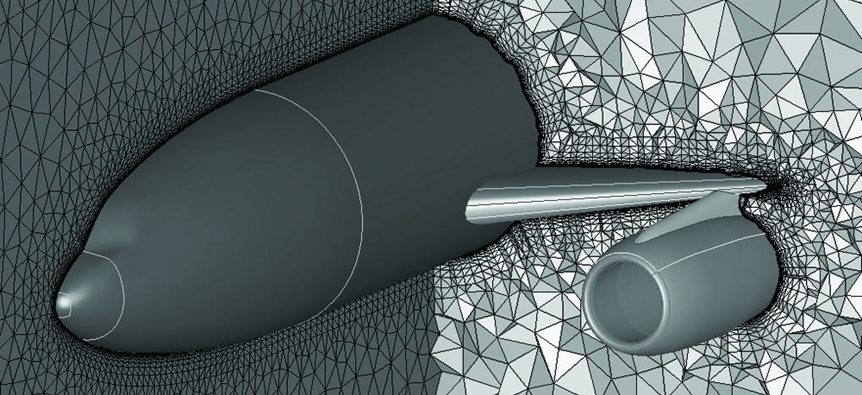

In the traditional mesh-based approach, the reliability highly depends on the quality of the mesh, and engineers spend most of the time

working on the discretization.

Furthermore, there are severe difficulties in dealing with the changes in the topology of the domain for problems involving the

presence of moving parts or fluid-structure interaction.

Why is XFlow so different to the current CFD solutions?

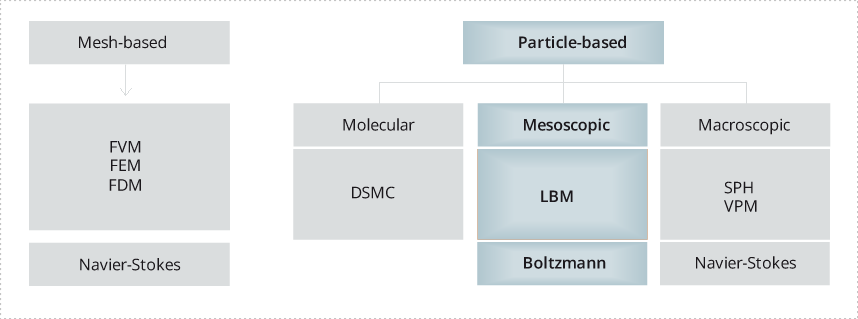

Simple – particle-based approach that avoids the traditional meshing process

XFlow is a next generation CFD software system that uses a proprietary state-of-the-art Lattice Boltzmann technology, and is

specifically designed for companies who require accurate feedback on flow simulation, transient aerodynamics, water management

and fluid-structure interaction.

The XFlow approach to CFD simplifies the workflow, minimizes the presence of algorithmic parameters and avoids the traditionally

time consuming meshing process.

With XFlow, complex modeling becomes affordable in a straightforward way.

Example of mesh required by traditional CFD

Unique CFD approach

How is XFlow different? What is going on inside?

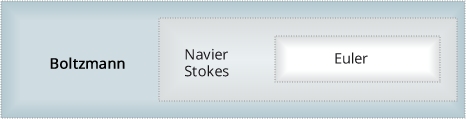

Beyond Lattice Boltzmann

In non-equilibrium statistical mechanics, the Boltzmann equation describes the behavior of a gas modeled at mesoscopic scale. The

Boltzmann equation is able to reproduce the hydrodynamic limit but can also model rarified media with applications to aerospace,

microfluidics or even near vacuum conditions.

As opposed to standard MRT, the scattering operator in XFlow is implemented in central moment space, naturally improving the

Galilean invariance, the accuracy and the stability of the code.

Particle-based kinetic solver

XFlow features a novel particle-based kinetic algorithm that has been specifically designed to perform very fast with accessible

hardware.

The discretization approach in XFlow avoids the classic domain meshing process and the surface complexity is not a limiting factor

anymore. The user can easily control the level of detail of the underlying lattice with a small set of parameters, the lattice is tolerant to

the quality of the input geometry, and adapts to the presence of moving parts.

Adaptive wake refinement

XFlow engine automatically adapts the resolved scales to the user requirements, refining the quality of the solution near the walls,

dynamically adapting to the presence of strong gradients and refining the wake as the flow develops.

Turbulence modeling: High fidelity WMLES

XFlow features the highest fidelity Wall-Modeled Large Eddy Simulation (WMLES) approach to the turbulence modeling.

The underlying state-of-the-art LES, based on the Wall-Adapting Local Eddy (WALE) viscosity model, provides a consistent local

eddy-viscosity and near wall behavior. It also performs in CPU-times similar to most codes providing just RANS analysis.

Single consistent wall model

XFlow uses a unified non-equilibrium wall function to model the boundary layer. This wall model works in most cases, meaning that

the user do not have to select between different models and take care of the limitations related to each scheme.

Advanced analysis capabilities

XFlow solver also features:

- Thermal analysis

- Flow through porous media

- Non-Newtonian flows

- Conjugated heat transfer

- Complex boundary conditions, including fan model or porous jump.

Software Environment

Unified environment for pre-processor, solver and post-processor

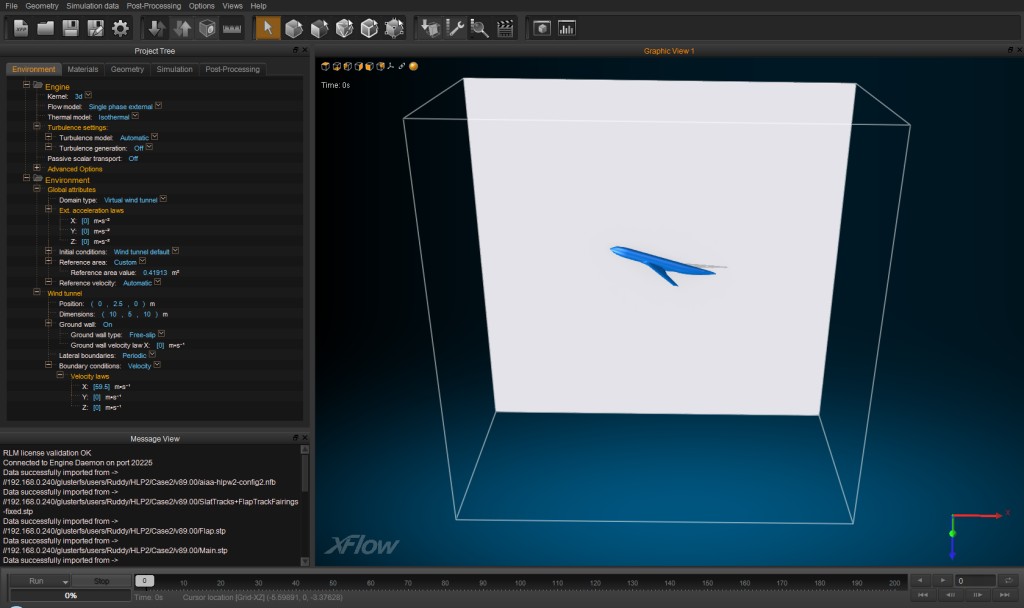

XFlow provides a unique and novel interface and working environment for the user. The pre-processor, solver and post-processor are

fully integrated in the same UI environment. The UI layout is fully configurable with moveable workspace windows and options to

use pre-set display settings.

Pre-processing Being particle-based, the algorithms behind XFlow lower the requirements imposed on the CAD models, e.g. for external aerodynamics the software is not concerned with moving or crossing surfaces as soon as these define a coherent fluid volume. Thus the complexity of the geometry is not a limiting factor in XFlow.

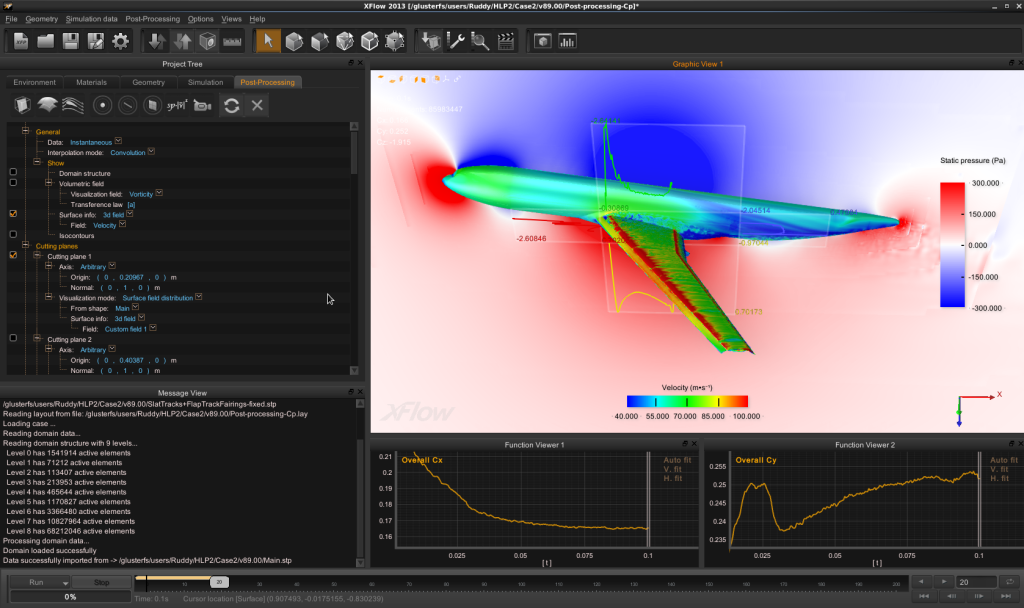

Post-processing The graphical post-processing capability of XFlow allows interactive visualization of the solution and allows numerical analysis even while the computation is still running. XFlow provides tools for additional processing through export to third-party applications such as ParaView and EnSight Gold

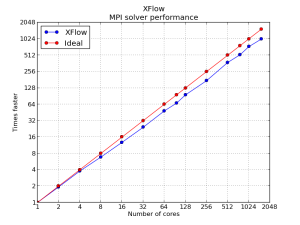

Near-linear scalable performance

|

|

| DMP XFlow also perfectly integrates into your HPC environment, which opens a wide range of possibilities for the most demanding computations. XFlow distributed solver scales efficiently even for a large number of nodes. |

SMP XFlow is fast, efficient and accessible even on a standard desktop PC. XFlow is fully parallelized for multi-core technology with near- linear scalability. |

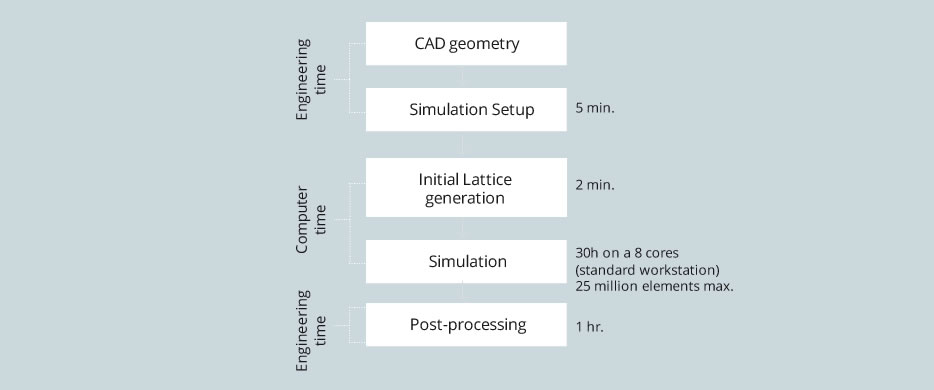

Process Time: Workflow example

XFlow drastically cuts the time spent on the preparation of the case, and the initial domain discretization. XFlow optimizes the

balance of your engineering and computer time costs.

Connectivity

XFlow provides a wide range of connectivity solutions, and we are always adding new connections.

Among the current connections are:

- Geometry

STEP, IGES and STL - User defined input

Functions and tabular data - FSI

One-way coupling to MSC.ADAMS

Two-way coupling to MSC.NASTRAN - Post-processing

Paraview and Ensight Gold