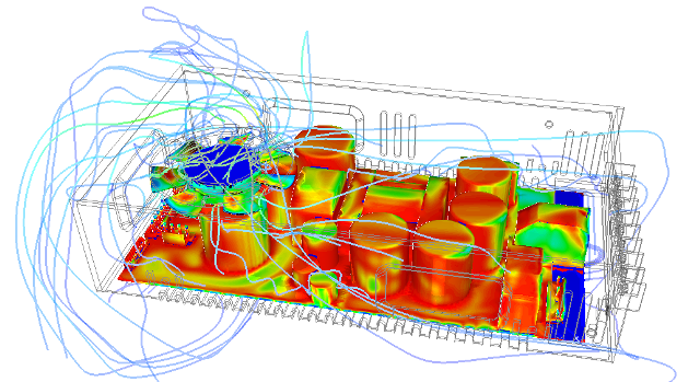

Thermal management

The thermal solver can be used to simulate the cooling of

electronic components to keep them within safe operating

temperature ranges. The simulation can include

convection/diffusion, radiation and conjugated heat transfer,

coupled to the flow produced by fans. Fans are modeled either

as rotating parts or as surface boundary condition.

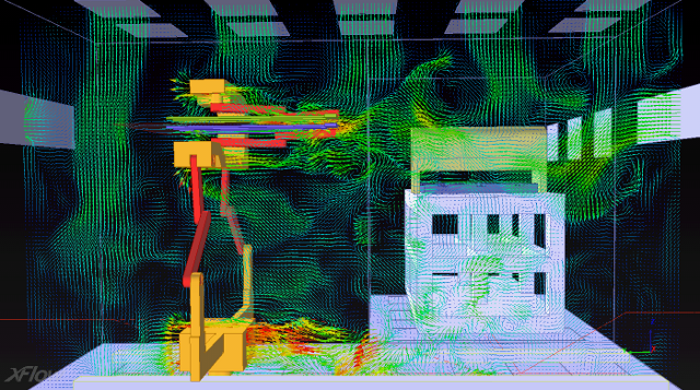

Robotized production systems

XFlow can simulate the flow around moving equipment such as

industrial machinery and production line robots in fabrication

plants. It is possible to prescribe the motion of each object and

so reproduce real operation conditions. The trajectories of dust

particles can be tracked with the disperse phase model.

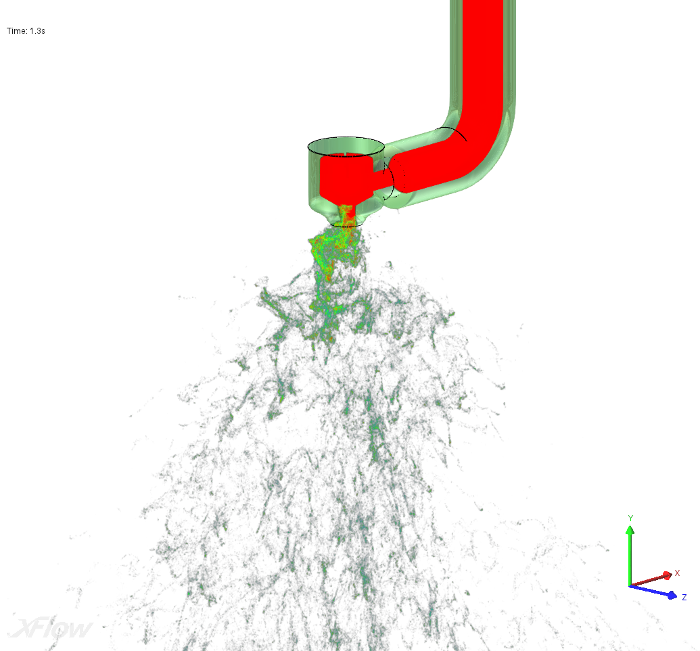

Mixing processes

XFlow can be used to simulate agitators and mixers for the

chemical industry or water treatment plants. It solves single and

two-phase flows for immiscible fluids including surface tension.

Stirrers can be modeled as rotating parts.

Non-Newtonian fluids

Highly viscous non-Newtonian fluids (e.g. toothpaste, melted

plastic, chemical blends) are common in many industrial

applications. The complex rheological properties of these fluids

can be introduced in XFlow by using the predefined viscosity

models available (Newtonian, Sutherland, Cross, Herschel-

Bulkley, Power Law, Carreau) or user-defined functions.

“The free surface approach in XFlow means nothing less than a

revolution in multiphase flow modelling of atomisation and

spray processes. I am convinced it will have a big impact on the

modelling of propulsion systems, fuel burners and a wide range

of different industrial spray processes.”

Dr. Hermann Maier, Managing Director of gridlab GmbH.